FN1-BV1W-3L (Wafer Butterfly Valve–Handle Operation)

●Brief

The product is composed of rubber sealed butterfly valve, carbon steel or stainless steel valve plate and valve stem. Suitable for temperature ≤ 80 ~ 120 ° C, such as food, medicine, chemical industry, petroleum, electricity.The water supply and drainage and gas pipelines of power, textile and papermaking are used to regulate the flow rate and cut-off medium.

●Features

1. The sealing element can be replaced, the sealing performance is reliable, and the two-way sealing is zero leakage.

2.The sealing material has the characteristics of aging resistance, corrosion resistance and long service life.

APPLICATION

General Use: Water,sea water,gas, pressurized air, acids etc.

CARACTERISTIQUES GENERALES

Resilient Seat Wafer Type Butterfly Valves Design according with BS EN593/APl609

Testing according with EN598.For Shell:1.5times Sealing:1.1times. Tightness in both ways.wafer type with smooth ears.Resilient seat adapted to the shape of the body assures low operating torque.Mounting flange according to ISO 5211

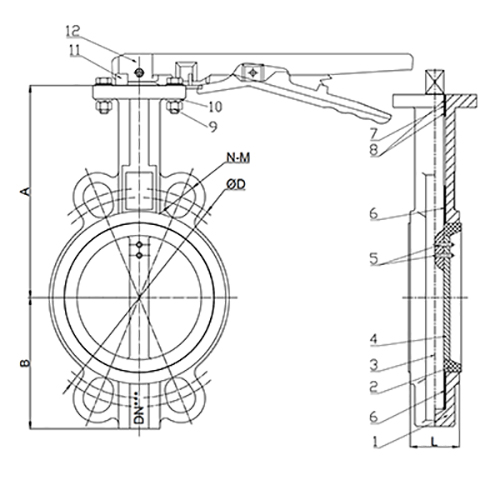

CONSTRUCTION

| NO. | PARTS | MATERIAL |

| 1 | BODY | Cl/ DI |

| 2 | SEAT | EPDM / NBR / VITON / SILICON |

| 3 | STEM | SS416 / 316 / 304 |

| 4 | DISC | DI / CF8 / CF8M |

| 5 | PIN | SS304 / 316 |

| 6 | O-RING | NBR/EPDM |

| 7 | BUSHING | PTFE / BRONZE |

| 8 | BOLT&NUT | STAINLESS STEEL / GALVANIZED |

| 9 | FLAT WASHER | STAINLESS STEEL / GALVANIZED |

| 10 | GEAR DISC | CARBON STEEL/ ALUMINUM |

| 11 | HAND SHANK | MALLEABLE IRON / AL / SS |

STANDARDS

Manufacture according to the requirements of the European directive 2014/68/EU, modulate H Face to face according to standards NF EN558 SERIE 20.ISO 5752,DIN 3202.

Mounting between flanges UNI EN1092:PN10/16 ANSl150,JIS10K,BS 10,TABLE E etc.

Body:24bar Seat:17.6bar